Electromagnetic ultrasonic non-invasive corrosion monitoring solution

During the use of oil and gas transmission pipelines, hazardous chemical pipelines in refining enterprises, storage tanks, etc., corrosive substances such as sulfides, water-soluble acids, and water-soluble alkalis are often present. Corrosion occurs when chemical or electrochemical multiphase reactions take place at the metal interface, causing the metal to enter an oxidized (ionic) state. This significantly reduces the mechanical properties of metal materials, such as strength, plasticity, and toughness, damages the geometric shape of metal components, increases wear between parts, shortens the service life of equipment, and can even lead to catastrophic accidents such as fires and explosions. The lack of long-term effective online monitoring and data analysis of on-site equipment for pipeline life prediction, excessively long intervals between major repairs, and the high difficulty of regular corrosion measurements for overhead pipelines create a demand for equipment capable of online corrosion monitoring of pipelines.

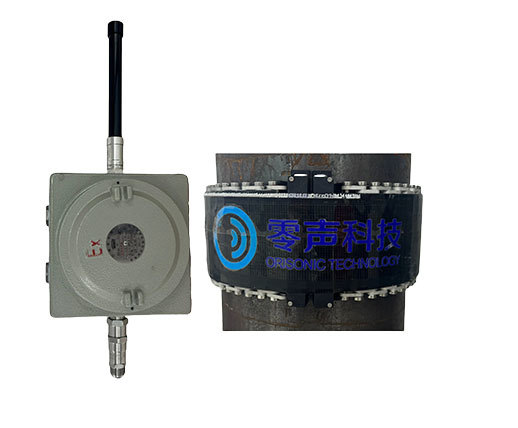

The zero-sound corrosion monitoring system is specifically designed for maintenance-free operation in harsh environments year-round. Combined with the unique electromagnetic acoustic transducer (EMAT), it can continuously measure pipe thickness, while the gateway receives the thickness data from the sensors via wireless transmission, thereby monitoring the trend of corrosion changes in real-time, ensuring the safety of industrial pipelines.