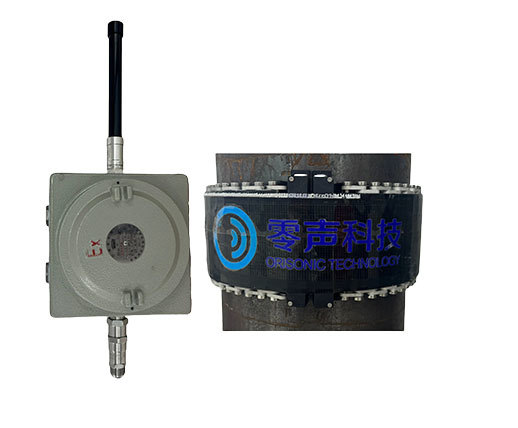

EMAT Corrosion Monitoring Sensor (Four-channel)

The ETM-100A-Q sensor system utilizes advanced electromagnetic acoustic transducer (EMAT) technology, providing continuous wall thickness measurements and real-time monitoring of corrosion and erosion trends. This sensor system supports four-channel probes, is a non-invasive monitoring device powered by batteries, and allows for quick and direct magnetic installation. With multiple communication methods, the system can reliably and accurately transmit data to the server, providing you with precise wall thickness information to optimize pipeline maintenance and replacement decisions.

Category:

- Description

- Characteristics

- Configuration

-

Measurement Principle Electromagnetic Ultrasonic Thickness Measurement Technology Coupling Method Magnetic Adsorption, No Coupling Agent Required Measurement Accuracy 0.01mm Thickness Measurement Range 1.5~75mm Pipeline Temperature -50℃- 250 °C Ambient Temperature -40℃- 80 °C Communication Protocol 4G/5G/NB-IOT/LoRa/RS-485 Protection Level IP68 Explosion Protection Level Ex d mb nA Ⅱ B T4 Gc Temperature Compensation Automatic Sound Speed Compensation Battery Life Over 5 years, replaceable battery -

► Supports four channels of simultaneous monitoring for more efficient pipeline monitoring

► Can be used on metal surfaces for service temperatures up to 498°F (250°C)

► Wall thickness sensors with EMAT technology for easy installation and continuous operation in downstream applications

► Supports multiple communication modes for safe, cost-effective and reliable technology

► Accurately identifies corrosion and erosion trends, avoiding inefficient and potentially unsafe manual inspection methods

► Simple, intuitive and non-intrusive installation, providing a fast automated solution with no wiring required

Tag: