Bolt axial force measurement solution

The domestic wind power industry is experiencing a rush to install, leading to a significant drop in installation prices. This has resulted in reduced margins for components, causing frequent accidents such as turbine collapses and blade fractures, with single repair costs reaching nearly ten million yuan. Among these, bolt fractures are the main cause of turbine collapses and blade fractures, with 80% of bolt failures attributed to inadequate preload (axial force) and poor installation and maintenance quality. Currently, the reliability and consistency of torque wrenches and other fastening equipment specified by national standards are poor, and the market lacks equipment capable of accurately measuring bolt axial force.

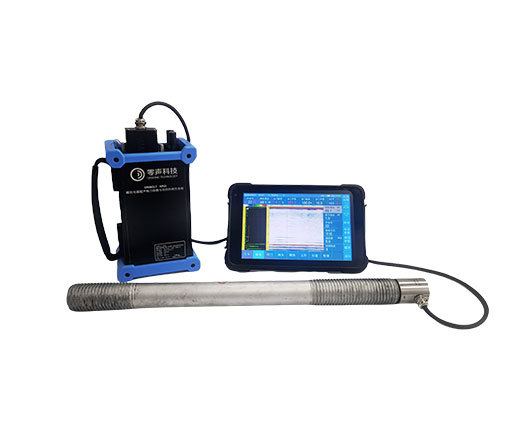

If the bolt preload is too high, the sealing gasket may be crushed and lose its elasticity, and may even break the bolt; if the bolt preload is too low, the residual compressive stress on the gasket surface after compression will not reach the working sealing pressure, leading to leakage in the connection system. Zero Sound Technology uses ultrasonic sensors to excite ultrasonic waves (both transverse and longitudinal) that propagate along the length of the bolt, and indirectly measures the bolt axial force by measuring the propagation time of the ultrasonic waves in the bolt and calculating it using a formula.